CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

Industrial CT makes alloy casting inspection more hassle-free! Chuangying Precision Helps You Reduce Costs and Increase Efficiency

In the manufacturing fields of automotive parts, machinery and equipment, are there hidden dangers such as porosity and cracks inside alloy castings? When the production volume is getting bigger and bigger, traditional inspection methods often face three major difficulties:

High risk of sampling: Defective parts are inevitably missed during mass production.

I can't keep up with efficiency.: It takes several minutes to inspect a piece, slowing down the entire production line.

Difficult to control costs: Destructive testing wastes material and results in significant annual losses

Chuangying Precision Industrial CT Inspection Service, with advanced technology to help you completely solve these problems!

Why choose Industrial CT?

Like a "non-invasive physical examination" of the casting, Tronox's sophisticated technology can:

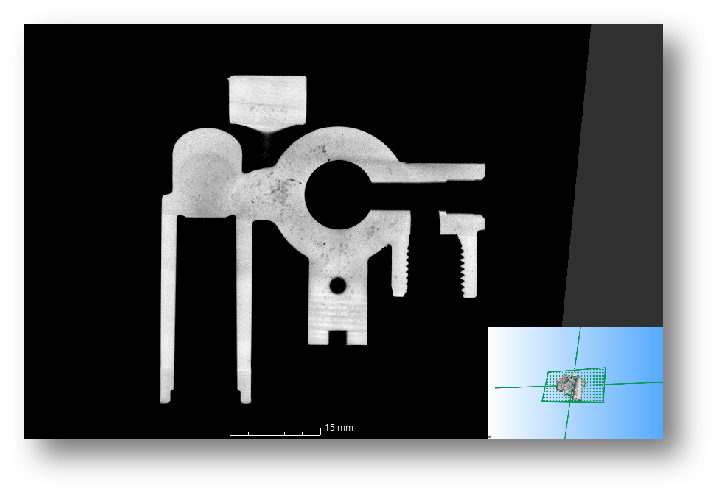

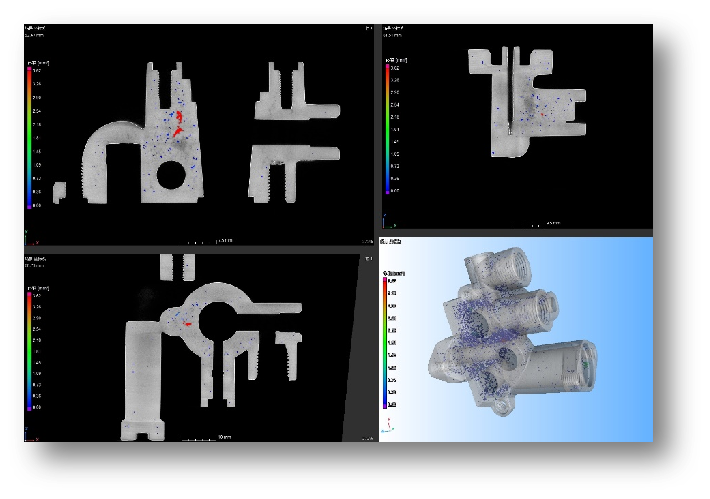

See the hidden dangers within: Accurately detects defects such as air holes, sand holes, cracks, etc. (flaws 30 times thinner than a hairline have no place to hide).

Omni-directional measurement: Automatic checking for uniform wall thickness and precise construction

No damage to the workpiece: The product is intact after testing and is used directly in production.

Three core advantages of Chuangying Precision

1. High-volume testing is easy

2. Immediate efficiency gains

3. Real cost savings