Industrial CT for circuit boards

Chuangying Precision: Industrial CT empowers circuit board quality control, batch high-speed inspection and low-cost worry-free

With the increasing precision and miniaturization of electronic products, the manufacturing quality and reliability of circuit boards (PCBA) have become the key to determining the vitality of products. Traditional inspection methods in the face of BGA, QFN and other hidden solder joints, internal defects stretched, not only time-consuming and laborious, but also unable to guarantee the efficiency and consistency of mass production. With advanced industrial CT technology, Chuangying Precision can precisely solve the pain points for the circuit board industry and open a new era of high efficiency and quality.

Industrial CT: A "non-invasive eye" for defects inside circuit boards

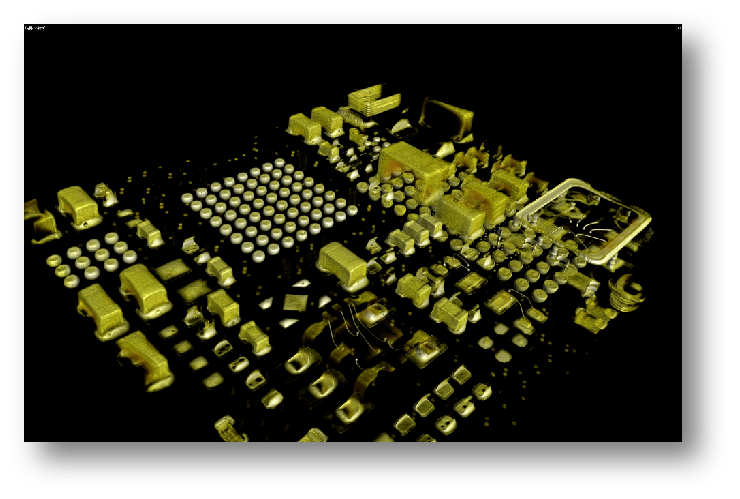

Industrial CT NDT technology integrates X-ray tomography and 3D reconstruction algorithms, breaking through the physical limitations of traditional inspection:

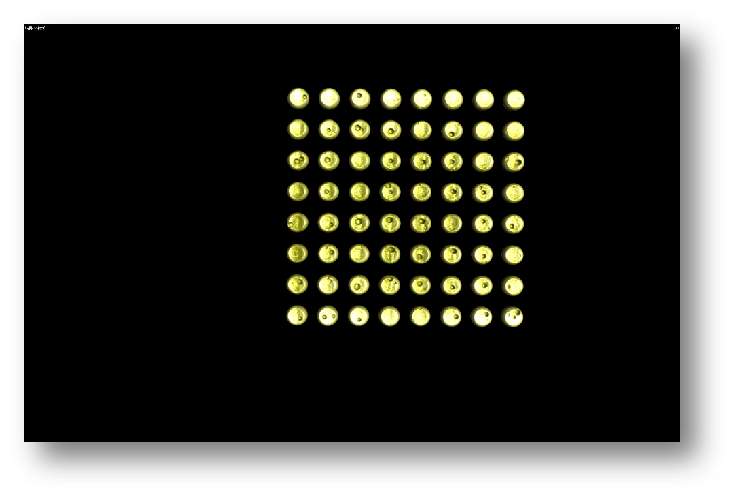

- thermal envelopeThe internal structure, soldering pattern, pin fullness, even ceramic capacitor micro-cracks, BGA soldering holes are clearly presented.

- three-dimensional presentation: Provide any angle slice view and three-dimensional modeling to accurately measure welding gaps, component offsets, underfill and other spatial issues.

- non-destructiveZero-contact, zero-damage inspection process, suitable for cost-sensitive components or single-board sample inspection.

CT services help you improve your quality control competitiveness.

✨High-volume, high-performance testing for speeding up production.

- The Chuangying Precision Industrial CT Inspection Equipment combines an automated positioning platform with intelligent software processing capabilities to realize thebulkHigh-speed continuous scanning of circuit boards.

- Optimized parallel reconstruction algorithms shorten the analysis cycle, helping customers to cope with the demands of high-density production inspection and ensure the rapid flow of products to the market.

⚡️Highly efficient one-stop service with short response times

- We specialize inTesting ServicesProcess optimization and streamlining from sample receipt to report output.

- Intelligent analysis software automatically identifies common defect types, engineers quickly review and confirm, and submit standard or customized inspection reports, significantly compressing the inspection cycle and improving efficiency.

💰Low-cost empowerment with significant input benefits

- Through intensive operations and mature service processes, Tron Image Precision controls veneer inspection costs at an industry-advantageous level.

- compared to the cost of expensive proprietary equipment or complex manual testing.inexpensiveInspection services help customers save upfront investment and comprehensive maintenance expenses, and easily achieve quality optimization and budget control.

Customization Capabilities of TranShadow Precision CT Equipment and Services

Chuangying Precision not only provides professional industrial CT inspection services, but also provides industrial CT inspection equipment sales and complete turnkey solutions for electronic manufacturing enterprises:

- Selected cost-effective industrial CT systems (micro-focus CT, nano-scale CT, etc.) to meet different precision needs.

- Customizable automated assembly line inspection solutions with deep integration of AOI/AXI and other electronic manufacturing links.

- Provide professional equipment installation, commissioning, training and long-term technical support to ensure smooth production operation.

Chuangying PrecisionAs a professional solution provider in the field of industrial CT, we are committed to providing the best solutions through the advancedIndustrial CTTechnical and professionalTesting Servicescapabilities to help electronics manufacturers efficiently realize their board quality control needs. We providebulk.high efficiency.inexpensiveOur testing services will be a reliable partner in upgrading the quality of your supply chain. Whether it's quality verification, failure analysis, or R&D sample evaluation, InnoPrecision can customize an efficient support solution.