CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

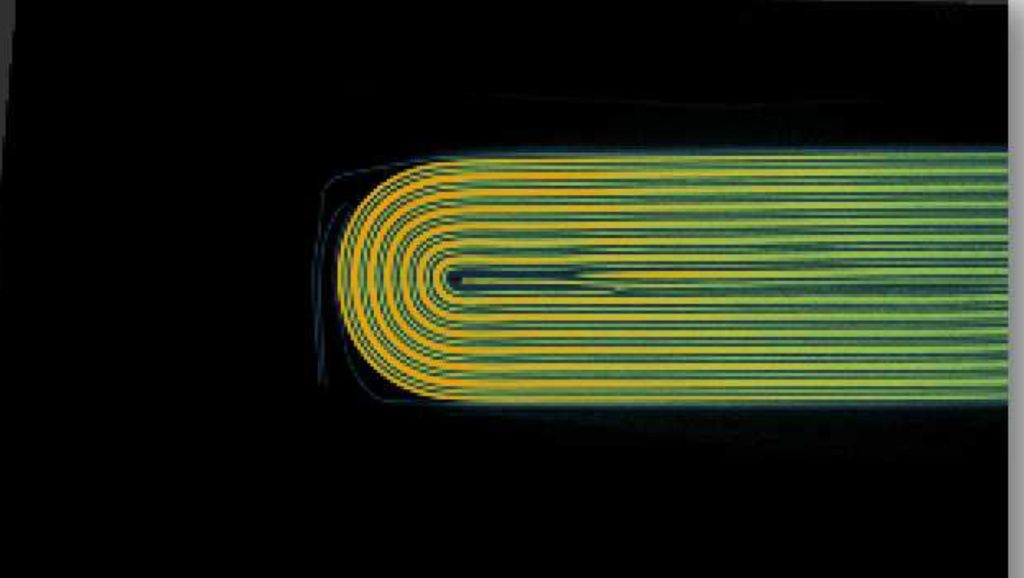

Industrial CT (Computed Tomography) is a non-destructive inspection technology that uses X-ray penetration and data collection, followed by algorithmic reconstruction to reveal the internal structure of the object under test. This technology plays a vital role in the quality inspection of 3C electronic products, as it can reveal internal flaws in detail without damaging the object itself.

3C electronic products are usually characterized by small size, complex structure, and high degree of integration, which puts forward extremely high requirements for quality inspection. Traditional inspection methods are often difficult to reach the interior of the product, and are unable to comprehensively and accurately assess its quality. Industrial CT technology can easily meet these challenges and provide strong support for quality inspection of 3C electronic products.

With its advanced industrial CT technology and professional inspection services, Chuangying Precision has achieved remarkable results in the field of 3C electronic inspection. The company has provided quality inspection services for a number of well-known 3C electronic product manufacturers, successfully detecting minor defects and hidden dangers within the products, effectively avoiding product quality problems. At the same time, Chuangying Precision also customized "software + hardware" solutions according to customer needs, helping customers to improve the level of quality inspection and production efficiency.

As a leader in the field of industrial CT inspection, Chuangying Precision, with its high-precision, omni-directional, non-destructive, and highly efficient inspection technology and services, provides a reliable guarantee for the quality inspection of 3C electronic products. In the future, with the continuous development and upgrading of 3C electronic products, Chuangying Precision will continue to plough into the field of industrial CT inspection and bring more technological innovations and high-quality services to the industry.