news Center

News Center

Industrial CT Technology Leader

Site-wide search

news Center

Industrial CT Technology Leader

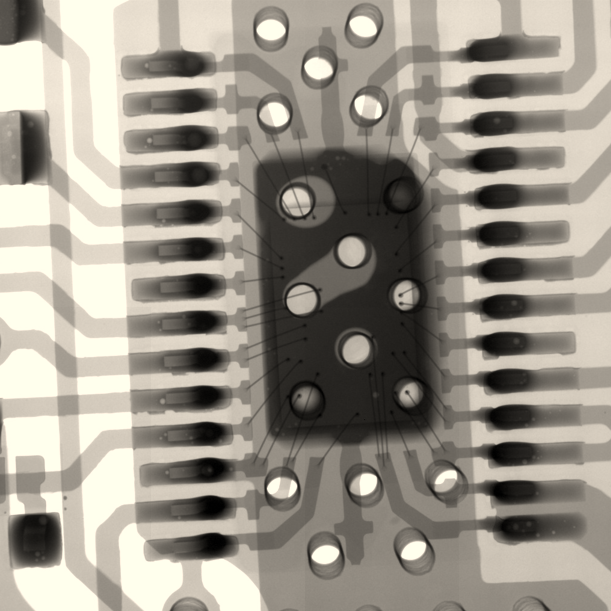

Industrial CT is an important tool used to provide detailed internal measurements of a workpiece and does not require disassembly of the part or product, making it a non-destructive testing method. A common advantage of industrial CT is its ability to construct three-dimensional images and analyze two-dimensional images of cross-sections generated during CT scans, in addition to three-dimensional models constructed for a variety of metrology and inspection applications. This not only shortens product development cycles, but also provides an efficient and simple method of quality control that might otherwise waste quality inspection time or even miss detected defects and reduce the accuracy of defect detection.

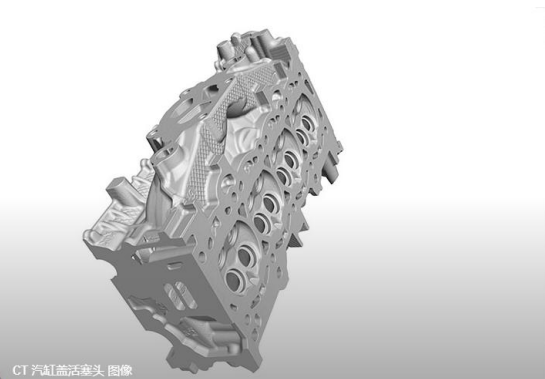

The high resolution of the tomographic image of the object under test obtained by industrial CT technology and, more importantly, the fact that industrial CT inspection is not limited by the geometry of the workpiece under test, and can be used to measure and verify the internal geometry of complex parts, and to be able to measure and report on the internal and external dimensions of the part, make computed tomography technology ideally suited for use on precision injection molded parts or other parts and assemblies whose internal geometry is not easy to analyze.

What's more, industrial CT technology has higher spatial and density resolution and wider adaptability for inspection at different gray levels. Wall thickness is another quality control factor for workpieces. Small variations in wall thickness throughout a part can interrupt the manufacturing or design process, resulting in high costs, especially for mass-produced parts. Industrial CT can detect and analyze industrial wall thickness data for quality control.

In addition to detecting dimensional defects, Industrial CT can also detect manufacturing defects, which play a critical role in both quality control and product development. Industrial CT can be used for porosity and inclusions verification, including identifying and pinpointing the location of high and low density areas throughout the part. The model obtained from the scan can also show the location and volume of inclusions and internal porosity, as well as calculate the percentage of porosity.

Industrial CT also has an obvious direction of development, the main way of detecting and identifying defects in the current industrial CT slice image is still human judgment by professionals, this identification method mainly relies on the experience of the detector, the detection results are often subject to the subjective judgment of the detector interferes with the results are not objective enough. With the arrival of big data, cloud computing, especially the quantum era, industrial CT combined with software, can realize the defect intelligent detection. Excluding the influence of human subjective consciousness on the detection results, with a large amount of actual data as evidence of defect identification, to improve detection efficiency while ensuring the accuracy of the results.

Industrial CT is equipped with professional intelligent identification and analysis software, which can realize batch on-line inspection of workpieces. Through flexible program software, it can realize automatic identification of defects on samples, which greatly improves the inspection efficiency.