PLANAR-Micro-Online-Industrial CT Equipment

Industrial CT/DR equipment

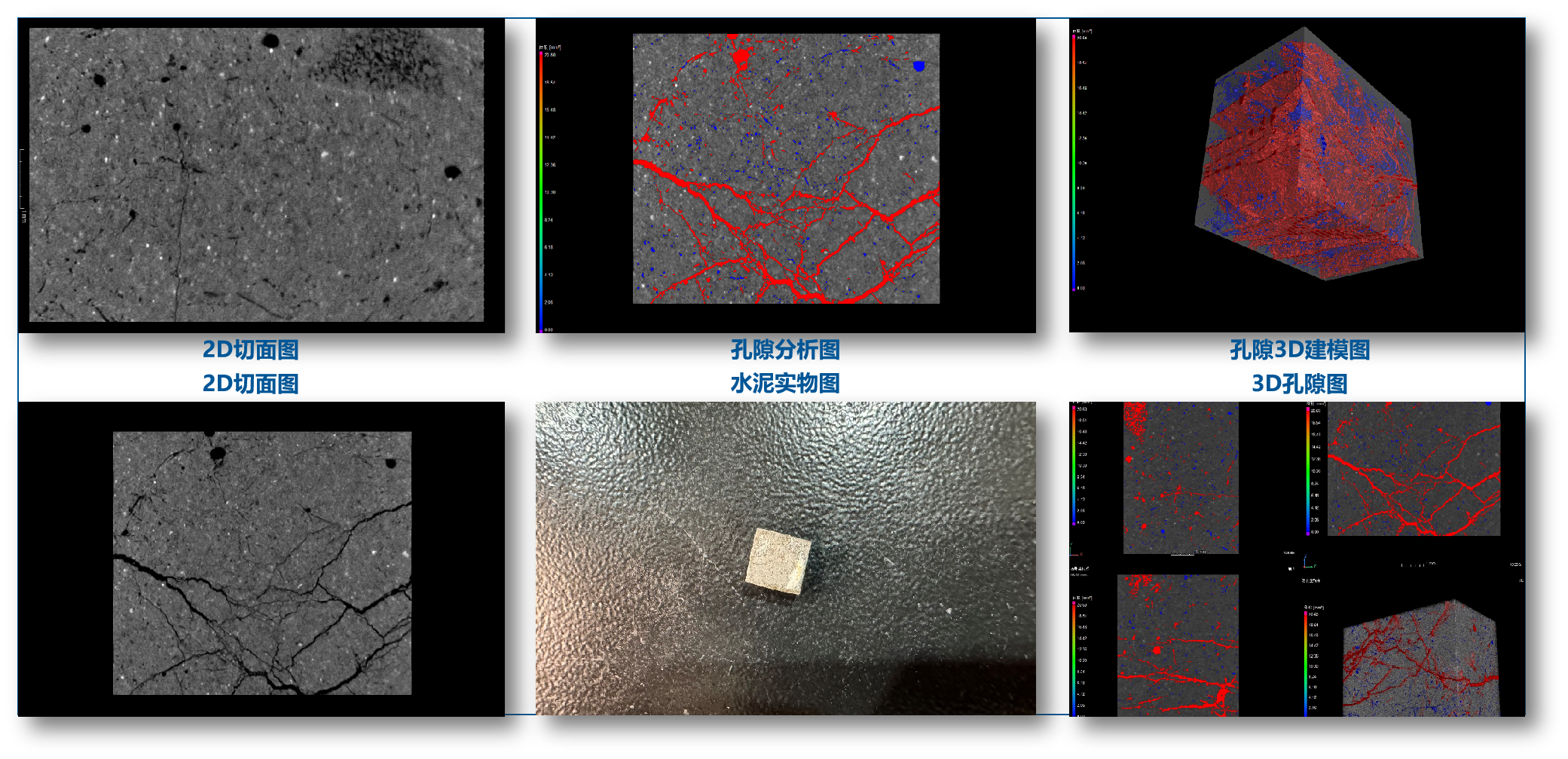

Intelligent AI image post-processing

Ultrafast | Large Area Layered Imaging | Software Integration | High Resolution

Product Advantages

Product Specification

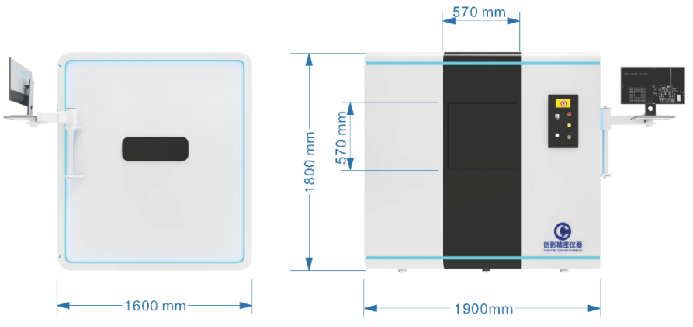

| Parameters of the whole machine | |||

|---|---|---|---|

| sizes | L1900*W1600*H1800mm | Supply Voltage | 220V AC |

| weights | 2 tons | power (output) | 2KW |

| X-ray Tube | |||

|---|---|---|---|

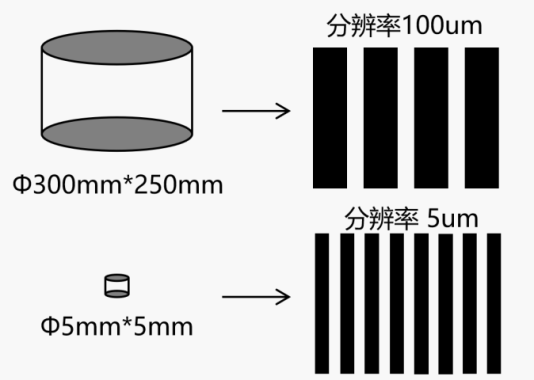

| Max Voltage | 90kv/110kv/130kv/160kv | Min Focal | 5um/2um/5umm |

| Imaging System | |||

|---|---|---|---|

| Detector Type | TFT/CMOS | Pixel Size | 49.5um-100um |

| Imaging Area | 12cm*7cm/16cm*16cm | Pixel Matrix | 1536*864/2940*230404 |

| Software System | |||

|---|---|---|---|

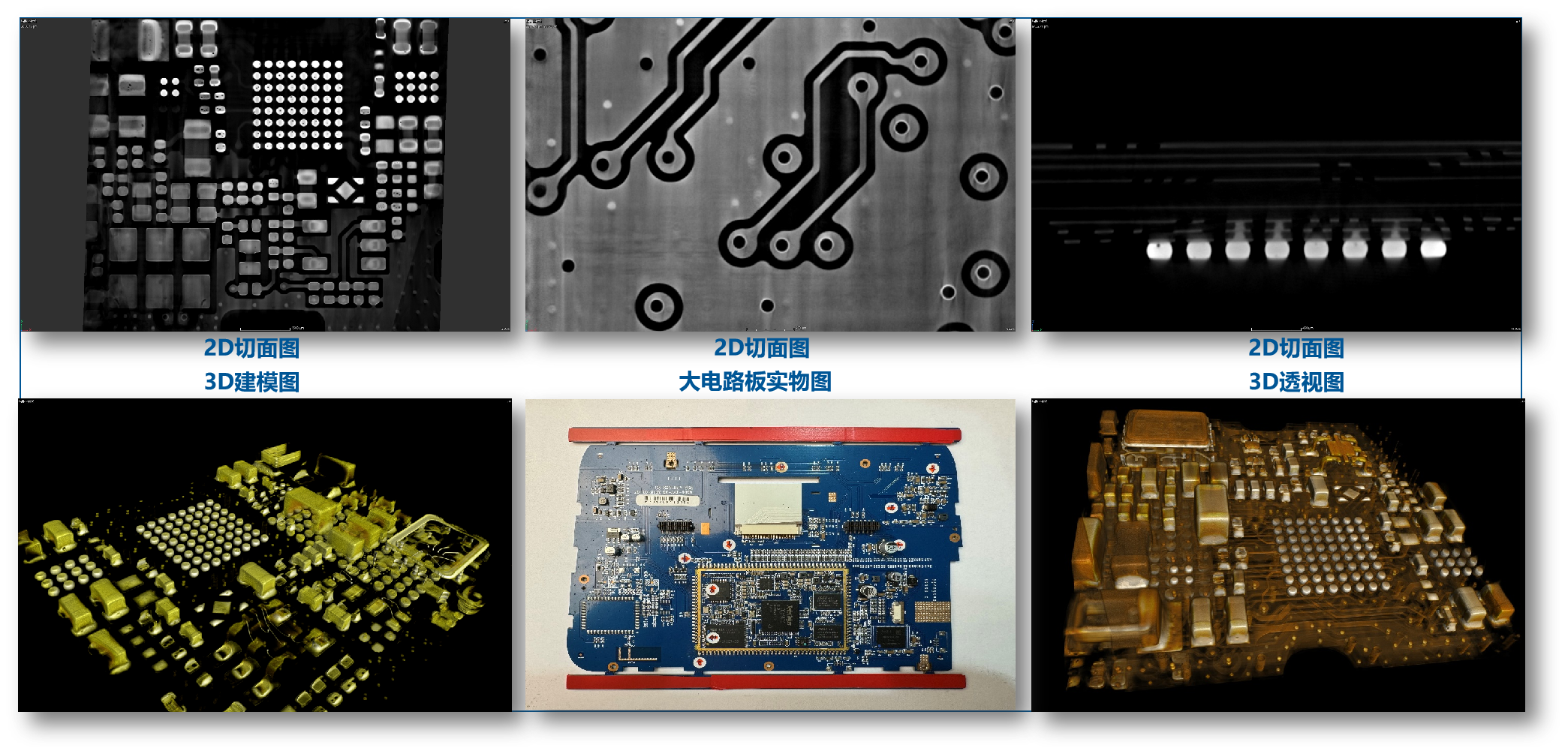

| Multiple CT modes | CBCT, Limited-Angle Mode, Extended Mode, Fast Mode | ||

| Real-time reconstruction | Real-time recon of batch samples, recon within 0 second | ||

| Scan Wizard Mode | Support users to operate step by step through the wizard, even beginners can make professional-grade effects | ||

| Software All In One | Operation + Reconstruction + Visualization + Analysis | ||

| Image Analysis | Advanced Processing Tools with AI Image Module | ||

| Motion Control System | |||

|---|---|---|---|

| Control Mode | Software & Joystick | Motion Axes | 5 |

| Max Sample | 600*600*100 (mm) | Max Detection | 500*500*100 (mm) |

| Max Load Weight | 10KG | ||

| Others | |||

|---|---|---|---|

| Door opening | Manual | radiation | <0.8uSv/h |

| Spatial Resolution | 5um/2um/5um | Scanning Speed | Max 20 sec/piece |

| Focal Length | 500mm | System Mag | 1000x |

Application Areas

Case Studies

3C electronics

Materials Research

semiconductor industry

Contact Purchase

Submit the form and a product manager will contact you within 24 hours!

Tron Precision

Tron Precision