CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

With the rapid development of modern manufacturing industry, casting as the core component of many industrial products, its quality is directly related to the overall performance and safety of the product. In automobile manufacturing, aerospace, machinery manufacturing and other high-precision requirements of the field, the non-destructive testing of defects within the castings is particularly important. Industrial computed tomography (CT) technology as a non-destructive means of detection, by virtue of its high precision, high resolution and intuitive three-dimensional imaging capabilities, in the field of casting inspection shows significant advantages. In this paper, we will discuss the application of industrial CT in casting inspection by combining the actual case of Chuangying Precision Company.

I. Overview of industrial CT technology

Industrial CT technology utilizes the penetrating nature of X-rays to receive the X-ray signals that penetrate the casting through a detector and convert them into electrical signals. These signals are processed by a computer to reconstruct a three-dimensional tomographic image of the inside of the casting, which in turn forms a three-dimensional model. This technique not only clearly shows the structure and details inside the casting, but also accurately identifies and measures a wide range of defects inside the casting, such as air holes, shrinkage holes, cracks, and inclusions.

II. Industrial CT Inspection Case of Chuangying Precision Company

As a company specializing in high-precision non-destructive testing, Chuangying Precision has advanced industrial CT inspection equipment and technical team. The following are a few typical cases in casting inspection by Chuangying Precision:

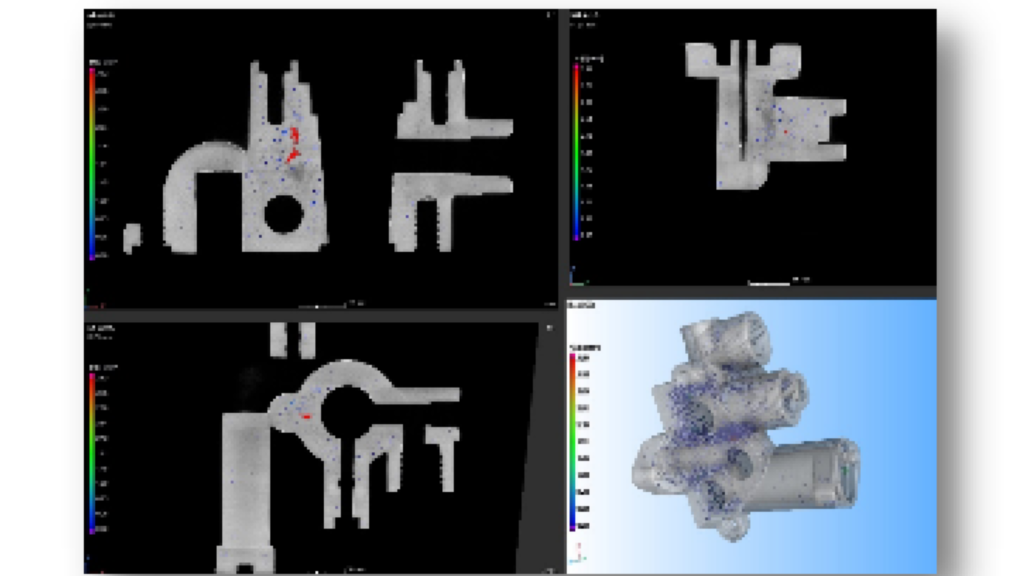

In the field of automobile manufacturing, aluminum alloy castings are widely used in key components such as engine blocks and transmission housings. These components have high quality requirements and require strict internal defect inspection. Chuangying Precision utilizes industrial CT technology to conduct a comprehensive internal defect inspection of aluminum alloy castings. Through three-dimensional imaging technology, internal defects such as porosity, shrinkage holes and cracks in the castings were successfully identified and measured, providing strong support for subsequent repair and design optimization.

In the field of machinery manufacturing, the internal structure of many complex mechanical parts is complicated, and it is difficult to comprehensively inspect their internal quality by traditional inspection methods. Chuangying Precision adopts industrial CT technology to inspect the internal quality of these complex mechanical parts. Through high-precision three-dimensional imaging and data analysis, it successfully found the tiny defects and foreign objects inside the parts, providing timely quality feedback and improvement suggestions for the manufacturer.

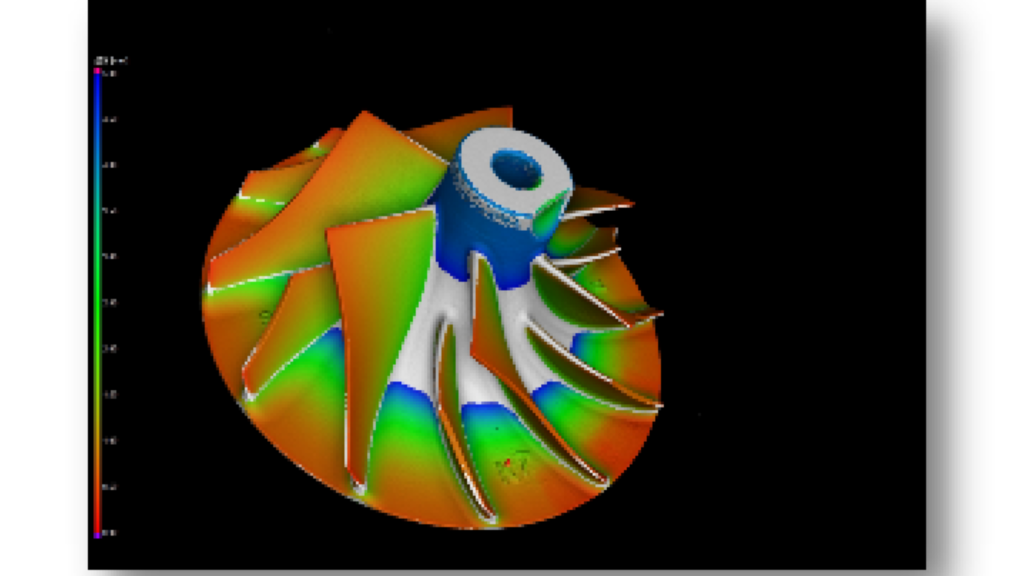

In the aerospace field, the internal quality of key components such as engine blades and turbine disks is directly related to the safety and reliability of the aircraft. Chuangying Precision utilizes industrial CT technology to perform rigorous internal defect inspection on these key components. Through non-destructive inspection means, cracks, inclusions and other defects inside the components were successfully identified and measured, providing an important basis for quality control and safety assessment in the aerospace field.

III. Advantages of Industrial CT Inspection

IV. Conclusion

Chuangying Precision has accumulated rich experience and successful cases in the field of industrial CT casting inspection. Through advanced industrial CT inspection technology and professional technical team, Chuangying Precision has provided high-quality NDT services for many industries. In the future, with the continuous progress of technology and the expansion of application fields, industrial CT will play an important role in more fields and provide strong support for quality control and safety assessment in manufacturing industry. Injecting new vitality.