CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

Under the background of accelerated global energy transition, lithium battery, as the core component of new energy vehicles and energy storage systems, its safety and consistency have become the key to industry competition. Industrial CT (industrial computed tomography) technology by virtue of theNon-destructive, three-dimensional, high-precisionThe testing capability is revolutionizing the quality control in the lithium battery manufacturing field. Combined with advancedIndustrial CT inspection equipmentThe company is able to realize the whole process of closed-loop quality from material, process to finished product, which protects the safety of lithium battery.

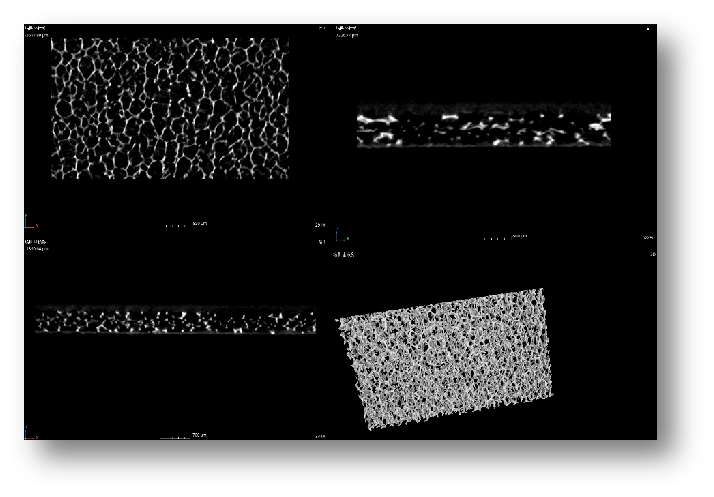

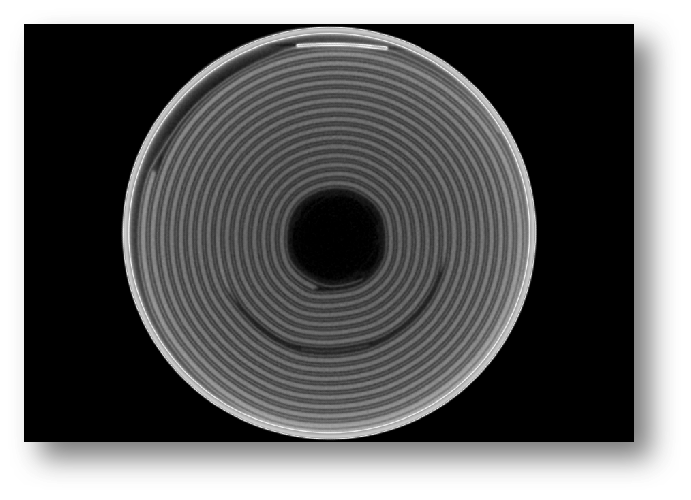

Industrial CT penetrates objects with X-rays and, combined with 3D reconstruction algorithms, provides non-destructive access to the interior of lithium batteries.Micrometer-scale three-dimensional structural data. Compared with the traditional two-dimensional X-ray or destructive slice inspection, industrial CT inspection not only clearly presents panoramic images of key parts such as electrode coatings, core roll stacks, welded joints, etc., but also accurately quantifies parameters such as porosity, alignment, and defect dimensions, which provides a scientific basis for process optimization.

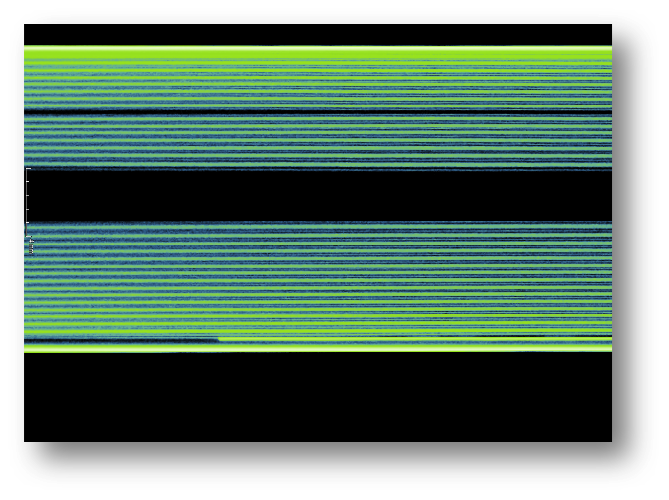

Industrial CT inspection allows for uniformity of pole piece coatingsFull-frame scanning analysisWith an accuracy of ±1μm, it accurately identifies problems such as fluctuations in coating thickness, uneven distribution of active substances or delamination at the collector interface. A head enterprise reduced the defect rate of coating process by 62% through the feedback of industrial CT data, which significantly improved the battery energy density.

Small defects such as metal foreign objects, pole piece burrs, diaphragm wrinkles, etc. are "invisible killers" that trigger thermal runaway. Industrial CT inspection can quickly identifyForeign matter over 50μmIt can also accurately locate the location of defects and avoid the flow of defective products into the terminal. For example, after the introduction of industrial CT inspection equipment in a power battery factory, the yield rate of the electric core has increased to 99.7%, saving over 20 million yuan in rework costs annually.

Laser welding depth of fusion, sealant filling integrity and other indicators directly affect the reliability of the battery. Industrial CT inspection can analyze the welded joints in a three-dimensional profile, quantify parameters such as porosity and consistency of melting depth, and at the same time, detect whether there are hidden problems such as delamination and wrinkles in the aluminum-plastic film encapsulation, so as to ensure the safety of the battery under extreme working conditions such as vibration and high temperature.

For batteries with capacity degradation or thermal failure after cycling, industrial CT inspection can non-destructively analyze the failure mechanisms such as lithium dendrite growth and pole expansion; in addition, by comparing the three-dimensional structure of competing batteries (e.g., winding tension, pole lug design), companies can quickly optimize their own processes and shorten the research and development cycle by more than 30%.

As a carrier of industrial CT technology, theIndustrial CT inspection equipmentThe performance of the new generation of equipment has a direct impact on inspection efficiency and accuracy. The new generation of equipment focuses on three core advantages:

Seamless integration of production linesIt supports all types of cylindrical, square and soft pack batteries, with a single cell inspection time of <2 minutes, compatible with automated production line requirements.

Ultra HD resolution: Using a micro-focused ray source with a highly sensitive detector, the spatial resolution is up to 0.5 μm, which can capture nanoscale defects.

Intelligent Analysis: Built-in AI algorithm library automatically identifies 20+ types of lithium battery defects (e.g., pole cracks, weld porosity) and generates visualized SPC reports.