Industrial CT in composites for research applications

Industrial CT: Core Solutions for Shadowtronic Precision to Drive Composites Research and Innovation

With their excellent lightweight and mechanical properties, composites are strategic materials in aerospace, new energy vehicles, high-end equipment manufacturing and other fields. However, the complex internal structure makes non-destructive and refined scientific research testing a great challenge. Traditional means often have limitations of insufficient precision or destruction of samples.

Industrial CT: The "scientific eye" for unlocking the inner world of materials

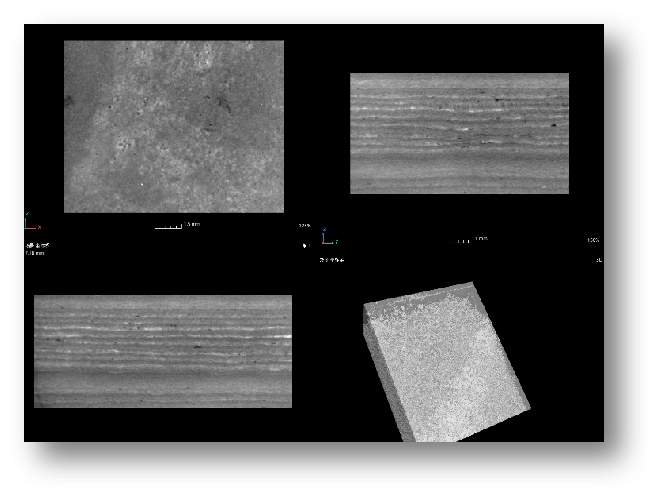

Industrial computed tomography (CT) technology, which utilizes X-rays to penetrate an object to obtain multi-angle projection data, and reconstructs high-precision three-dimensional models by computer. It is irreplaceable in composites research:

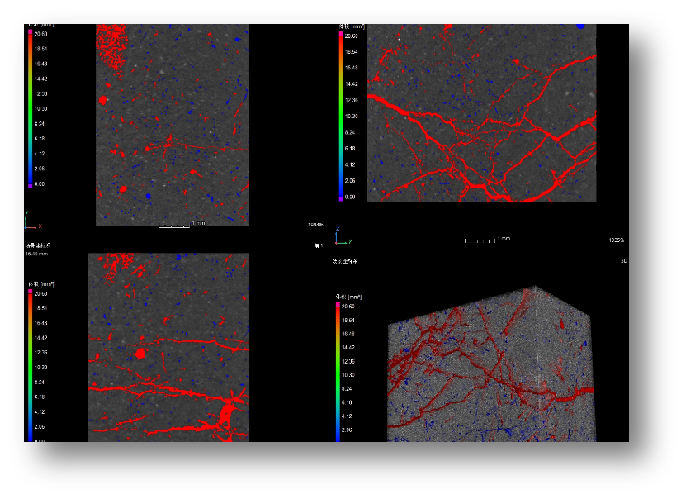

- Non-destructive perspective.Key internal information such as fiber arrangement, porosity, interfacial bonding, delamination damage, etc. are clearly presented in a non-destructive state.

- 3D Data Treasure.Provides complete internal 3D structural information to support volumetric measurements, defect localization analysis and reverse engineering applications.

- Quantification and dynamic tracking.Accurate measurement of damage size and distribution, and can be used for dynamic tracking of material failure mechanisms under multi-field coupling conditions such as heat and force.

Chuangying Precision: The Industrial CT Solution Specialist for Research Empowerment

TranShadow Precision has been deeply engaged in the field of industrial CT for many years and is committed to providing the composites research community withHigh efficiency, high volume, low costof specialized solutions:

- High-performance industrial CT systems.

- Equipped with micro-focus and nano-focus ray sources, it meets the demand for full-scale resolution from macroscopic components to microscopic reinforced fiber structures.

- Modular design supports flexible configuration of multiple scenarios, accurately adapting to the inspection needs of various composite material samples.

- Provides research-grade and industrial-grade equipment sales services to help build capacity in cutting-edge laboratories.

- Strong professional testing service capability.

- High-volume data processing.Relying on advanced GPU clusters, it has the ability to process massive high-resolution CT data to support the progress of large-scale scientific research projects.

- Efficient Processes.Standardized operating procedures and automated scanning modes significantly shorten the research and testing cycle and reduce time costs.

- Low-cost research inputs.Compared to the huge investment of building your own labs, Innofidei's precision testing service significantly reduces the cost threshold of research projects and frees up resources to focus on core innovations.

Application Value.

- Mechanism depth insights.Provide accurate data support for basic research on composite material damage evolution, interface behavior and fracture mechanism.

- Manufacturing process optimization.Identify causes of internal defects such as porosity, dry spots, etc., and guide the optimization of molding processes (e.g., hot press tanks, RTM).

- Performance is reliably predicted.The establishment of a real structure model provides reliable input for simulation calculations and significantly improves the accuracy of life prediction.

With the cutting-edge technology and professional ability of "seeing the invisible", Chuangying Precision helps composite material researchers to break through the traditional research limitations, explore the unknown mysteries inside the materials, and accelerate the scientific and technological innovation from the laboratory to the industrialized application.

Driving composites research and innovation starts with precise insights!

Industrial CT solutions for scientific research.Whether you seekHigh efficiency, high volume, low costFor testing service support or planning to set up a cutting-edge industrial CT lab, TranShadow Precision is your reliable partner.