CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

Industrial CT: Unlocking the inner mysteries of aerospace parts, Chuangying Precision helps you fly higher, safer and more economically.

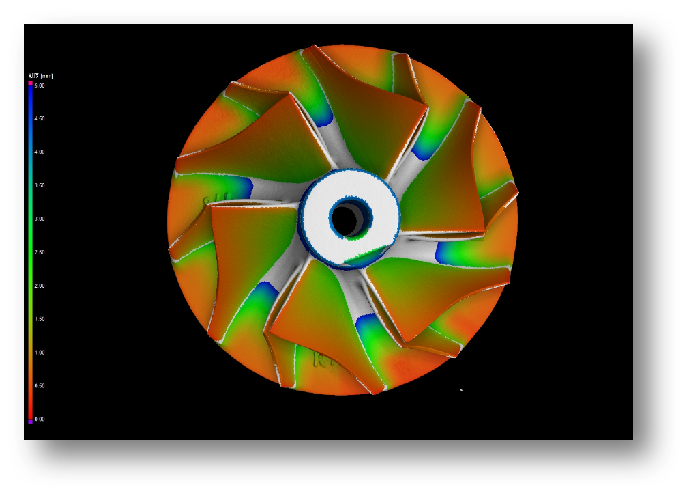

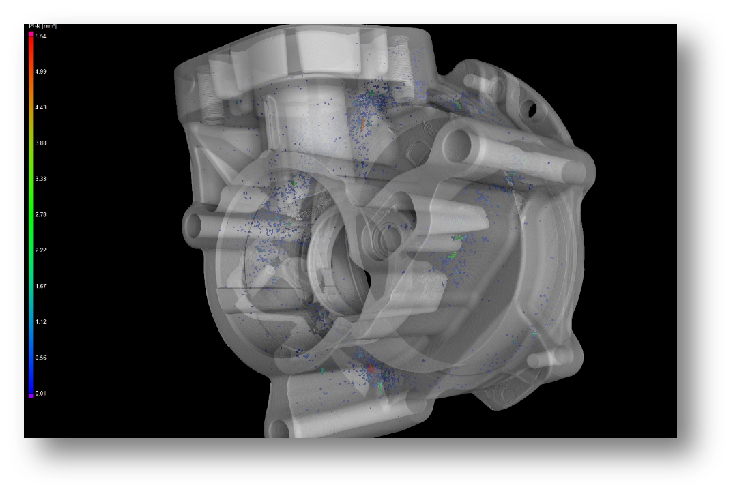

In the aerospace industry, which seeks the ultimate in safety and performance, the internal quality of every component is a make-or-break proposition. Small defects and structural deviations can have catastrophic consequences. However, traditional inspection methods such as slicing, ultrasound, and radiography are difficult to visualize complex internal structures, time-consuming, costly, and unable to meet the demands of modern aerospace manufacturing.bulkSpare parts implementationHigh efficiency and low costThe rigid need for comprehensive testing. How can this pain point be broken through?

Industrial CT technology has revolutionized aerospace quality control with its ability to see in three dimensions:

TranShadow Precision deeply understands the aerospace industry's need forHigh volume, high efficiency, low costThe core demand of inspection, to create a specially optimized for the harsh industrial environment of industrial CT inspection solutions and services:

The value of "one-stop" services.After detecting the problems, relying on the professional team to provide solution suggestions to help optimize the process and reduce the scrap rate.Realization of overall cost savingsThe. Machine.

Built for "high volume".

High throughput scanning system.Equipped with a high-speed detector and a powerful X-ray source, it significantly reduces the scanning time of a single piece, making it easy to cope with the pace of the production line.

Automated process integration.Support robot automatic loading and unloading, pallet feeding system, seamless integration of automated production lines, to realize the7×24 hours unattended and efficient operationThe

Standardized inspection templates.Rapid application of pre-fabrication programs to parts from the same lot ensures that theconsistencyThe newest version of the program, the newest version of the program, is the one that will save you a lot of setup time.

Pursuing the ultimate in "efficiency".

Intelligent Analytics Software Driver.Adopting advanced AI-driven software, automatically locating, measuring, comparing defects and dimensions, and intelligently generating inspection reports.Reduce manual analysis time by more than 90%The

"One-click" report output.Customized report templates to quickly generate traceable reports containing detailed defect pictures and data tables to meet airworthiness certification requirements.

Experienced technical team.Provide professional scanning program development, data analysis and report interpretation services, help you toRapid access to critical quality information to accelerate decision makingThe

Realization of "low-cost" commitments.

Alternative to destructive testing.Avoiding the destruction of expensive prototypes saves material and time costs.

Reduced manpower dependency.automated processes combined with intelligent software.Significantly reduce manual operations and specialized analytical laborThe