CASE ANALYSIS

Case Study

Industrial CT Technology Leader

Site-wide search

CASE ANALYSIS

Industrial CT Technology Leader

Industrial CT Technology: Enabling 3D Printing Quality Innovation, Opening a New Chapter of Intelligent Manufacturing

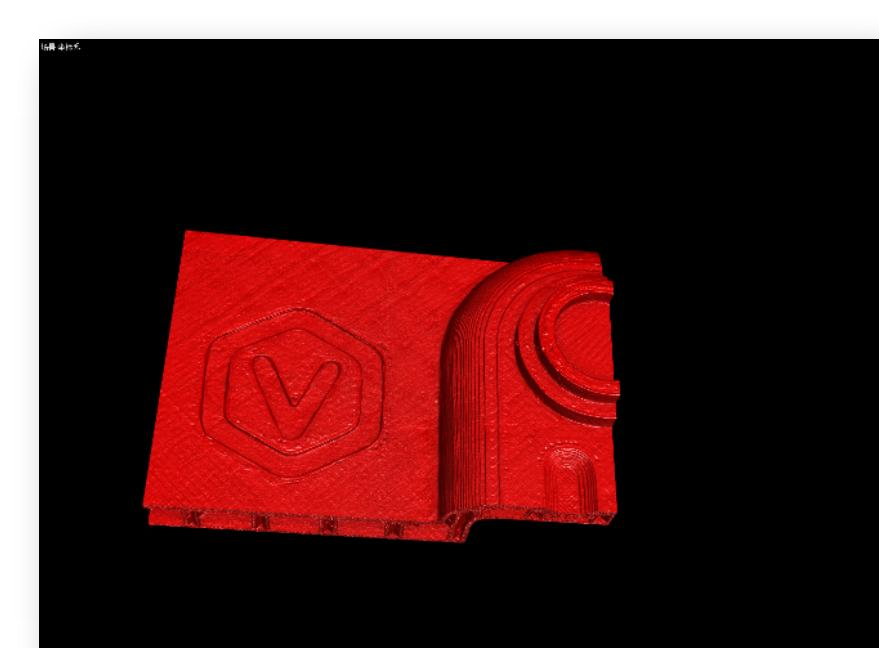

In the era of intelligent manufacturing, 3D printing technology has become one of the core technologies in the industrial field by virtue of its advantages in rapid prototyping and complex structure manufacturing. However, as the industry's requirements for product precision and reliability increase, how to ensure the internal quality of 3D printed parts has become a core issue of concern for enterprises. In this context, theIndustrial CT technologyWith its non-destructive testing, high-precision three-dimensional imaging and other capabilities, it has become a key tool for the quality control of the whole process of 3D printing, helping enterprises realize the leapfrog upgrade from "manufacturing" to "smart manufacturing".

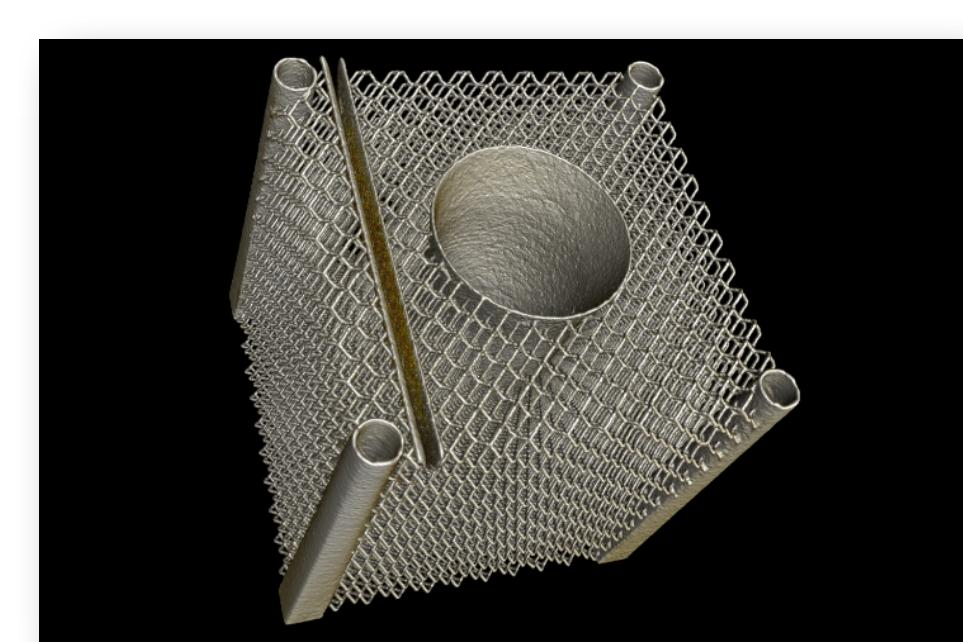

Traditional inspection methods (e.g., ultrasound or X-ray 2D imaging) are difficult to fully assess internal defects (e.g., porosity, cracks, unfused, etc.) in 3D printed parts, and theIndustrial CT InspectionThrough high-energy X-rays penetrating the object, combined with 3D reconstruction technology, the printout can be scanned in an all-round, non-destructive three-dimensional way to precisely locate the position of defects and quantitatively analyze them.

Core value embodiment::

From prototyping to mass production.Industrial CT equipmentThe application of the 3D printing through the whole life cycle, to provide enterprises with the whole chain of quality assurance:

Industrial CT can perform 3D scanning on complex prototypes or parts that are difficult to manufacture by traditional processes, generating high-precision digital models and providing accurate reverse design support for 3D printing. At the same time, by comparing the CT scanning results with the original design data, it can quickly verify whether the product achieves the expected structural accuracy.

Partially advancedIndustrial CT equipmentSupporting online inspection function, you can monitor the critical areas in real time during the printing process, timely detection and correction of defects, to avoid the waste of materials and time.

For high-end sectors such as aerospace and medical devices, industrial CT inspection is a "hard standard" for finished products before they leave the factory. For example, in the case of metal 3D printed impellers or orthopedic implants, CT technology ensures that the internal structure is fully compliant with stringent industry specifications.

In the face of the market's diverseIndustrial CT equipmentThe company needs to focus on the following core indicators according to its needs:

With the breakthroughs in artificial intelligence and big data technologies, industrial CT is moving towards theintellectualizetogether withmake more efficientDirection evolution:

With 3D printing technology reinventing manufacturing today, theIndustrial CT InspectionIt is not only the "gatekeeper" of quality control, but also the core driving force for process innovation and cost reduction. As a leadingIndustrial CT equipmentand solution provider, [company name] is committed to providing enterprises with high-precision and high-efficiency inspection services, empowering 3D printing technology to break through the quality bottleneck, and helping customers seize the first opportunity in the wave of intelligent manufacturing!